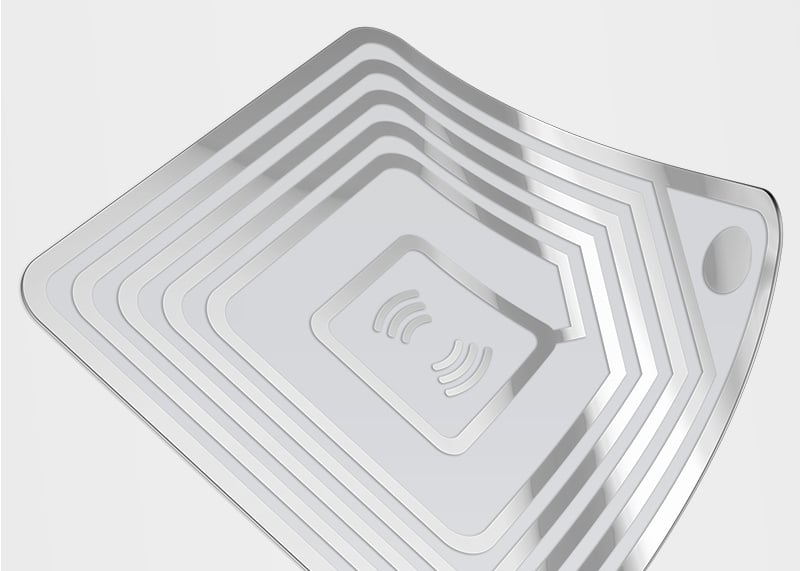

Discover the power of intelligent labeling with RFID.

Walmart and other major retailers promote RFID compliance. Nosco’s RFID label inlays and RFID carton inlays are designed to meet these requirements – enhancing safety, traceability and ensuring compliance, all while addressing current and future needs for intelligence in packaging.

Key Benefits of Nosco's RFID Solutions

Supply Chain Transparency

Track and manage inventory with real-time data.

Improved Inventory Control

Optimize inventory management and reduce errors.

Enhanced Security

Prevent theft and counterfeiting with location and inventory tracking.

Improved Customer Engagement

Enable unique branding experiences for consumers to tell your brand story.

The Nosco Difference

Nosco’s Solutions Engineering team will partner with you to make the RFID specification process as easy and seamless as possible. Whether you have a spec in mind, or need our help in developing and perfecting it, our team of experts will support you through design, specification, inlay placement, evaluation and testing, including cGMP compliance and ultra high frequency (UHF).

Nosco stands out in the market by offering the ability to integrate RFID technology into current product label specs. Plus, our labeling engineers are well-versed in addressing the technicalities of RFID integration for a variety of applications.

Compliance with Retail Mandates

Nosco's RFID solutions include ARC-certified RFID labels, ensuring seamless compliance with Walmart and other leading retailers. ARC certification, provided by Auburn University, guarantees that our RFID labels meet the performance standards required by major retailers. This certification ensures reliability across supply chains, helping suppliers avoid costly disruptions and confidently meet retailer mandates.

Leading Applications

Retail

Accurate inventory management and dynamic pricing.

Food & Beverage

Monitor expiration dates and reduce food waste.

Healthcare

Authenticity verification and inventory management.

RFID-a-Sure™

RFID-a-Sure™ seamlessly combines printed folding cartons and RFID tags to simplify the converting process. This solution is available for digitally or conventionally printed folding cartons with windowing, highly decorative embellishments and finishes.

Added Value

- Faster line speeds

- Less sourcing and labor requirements

- Assurance of correct RFID inlays

Contact us to learn more about RFID-a-Sure™ and Tag-a-Sure™.

UHF Benefits

Ultra high frequency (UHF) RFID tags operate within a frequency range of 860 to 960 MHz. These RFID tags enable the reading of contents inside boxes, cargo containers and other enclosed spaces, providing enhanced visibility and tracking capabilities without the need for direct line of sight. Some of the other notable benefits of UHF label inlays include:

- Case and pallet orientation

- Less costly

- Global UHF technology

- Metal and/or liquid sensitive

- Orientation sensitive

Interested in learning more about RFID?

Download our free whitepaper to take an in-depth look at the role of RFID tags in printed packaging, their benefits and key applications.

Interested in learning more about RFID?

Nosco Expands RFID Offerings

Nosco is excited to announce a new strategic partnership with industry leader Avery Dennison, strengthening our position in RFID packaging solutions. Read more >

RFID Expansion

Nosco has launched its new Tamarack at the Packaging Innovation Center, which is 16 times more productive with faster speeds and multiple lane capabilities. Read more >

RFID Whitepaper

Download our free whitepaper to take an in-depth look at the role of RFID tags in printed packaging, their benefits and key applications. Download whitepaper >

Get started with RFID.

Fill out the form below to learn more about how Nosco's RFID solutions can benefit your business.